Contact Us

Please complete the form below and a B&D Plastics representative will be in contact with you as soon as possible.

Viega is a global leader in innovative press fit solutions, committed to delivering superior quality, efficiency, and reliability. With a legacy spanning over 125 years, we continue to revolutionise installation technology through cutting-edge press systems and smart solutions designed to enhance performance, safety, and sustainability.

Viega Ltd has been serving the UK markets for over 15 years, officially establishing its presence in 2014 to deliver high-performance solutions tailored to fluid handling for industrial applications. As part of our commitment to offering cutting-edge technologies and materials, B & D Plastics Group Ltd is proud to partner with Viega Ltd in supporting the UK’s evolving industrial sectors.

Through this collaboration, B & D Plastics Group Ltd leverages Viega’s advanced piping systems alongside our own specialist expertise in thermoplastics pipework supply and fabrication. Together, we provide integrated, durable, and efficient solutions for clients across sectors such as Water Treatment, Food and Beverage, Chemical Processing and Manufacturing.

This partnership ensures our clients benefit from:

By aligning with trusted global brands like Viega, B & D Plastics Group Ltd continues to deliver added value, reliability, and innovation to every project we support.

A reliable system made of high-quality materials. Sanpress Inox is made entirely of high quality stainless steel. The stainless steel press connectors are equipped with extremely durable EPDM sealing element. The matching 316 stainless steel pipes and fittings are flawlessly hygienic and offer complete installation flexibility.

In hygienically sensitive areas such as hospitals or food processing factories, stainless steel press connector systems are always the best choice. Viega Sanpress Inox is a complete stainless steel system comprising press connectors and piping of the highest quality. The extensive range of parts and components enables you to create installations for drinking water and industrial applications that incorporate long-term safety, from the riser pipe to the final draw-off point. This makes Viega Sanpress Inox the answer to virtually any challenge when installing drinking water systems.

Double press – for twice the benefit

Pressing is conducted both in front of and behind the connector bead, thereby guaranteeing a durable, torsion-resistant and force-fit longitudinal connection.

SC-Contur: a small contour for maximum reliability

Easy to detect unpressed connections. Dry leakage test (22mBar to 3 Bar) or Water leakage test (1Bar to 6.5Bar)

Product marking – no risk of confusion

Uniquely marked. The colour of the markings stand for the different areas of application (Green : Drinking Water / Yellow : Gas)

Using the pressing technique to connect piping significantly reduces installation time. Much less effort is required compared to conventional methods such as welding or soldering, and it can even be used in hard-to-reach areas. System elements can be joined in less than 20 seconds, reducing assembly time by up to 80%.

With stringent quality standards, high-quality materials and continuous innovations, Viega ensure reliable press connections. The ‘SC-Contur’ feature makes any, inadvertently unpressed connections, clearly visible. It is included in all press connectors and enables a centralised leakage test to be performed.

Viega press connection technology is an effective and efficient way to save both time and money. Not only does it eliminate the special steps associated with processes such as welding or soldering, but the pressing method also makes the system less prone to faults and therefore more durable overall.

Viega press connection technology is an effective and efficient way to save both time and money. Not only does it eliminate the special steps associated with processes such as welding or soldering, but the pressing method also makes the system less prone to faults and therefore more durable overall.

No flames or fumes are generated when pressing pipe connections and the process is absolutely fireproof. This reduces the risks posed by flying sparks or human error – a major advantage, especially in sensitive or hard-to-reach environments. It also minimises the need for special health and safety measures and permits.

No flames or fumes are generated when pressing pipe connections and the process is absolutely fireproof. This reduces the risks posed by flying sparks or human error – a major advantage, especially in sensitive or hard-to-reach environments. It also minimises the need for special health and safety measures and permits.

With over 800 press connectors and components made of high-quality stainless steel (316 & 314), the Sanpress Inox system offers a comprehensive solution for drinking water, heating and cooling systems, particularly in hygienically demanding environments.

Available in dimensions from 15 to 108 mm – and meets the highest quality standards and is certified according to ÖVGW and DVGW requirements.

Thanks to the straightforward installation process using the Viega Pressgun and corresponding pressing jaws, Sanpress Inox is ideal for creating reliable and durable installations for industrial applications.

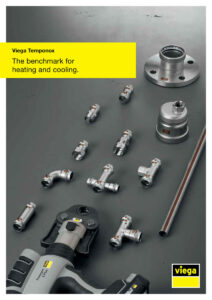

The Viega Temponox system delivers reliable performance for raised temperature, chilled water, and non-potable water applications across a wide range of industrial uses.

Manufactured from high-grade stainless steel, Temponox offers outstanding corrosion resistance and long-term operational durability.

The system’s extensive range of components supports versatile configurations to suit diverse process and industrial applications. With a wide selection of press-fit connectors—including elbows, flanges, and adapters—Temponox ensures secure and efficient fluid transportation in demanding environments.

Its compact design allows for space-saving installations, particularly in skid and kiosk builds. Engineered for strength, efficiency, and cost-effectiveness, Temponox is the ideal choice for industrial systems requiring dependable and maintenance-friendly performance.